Origin of PDT

Phonon Diagnostics Technique (PDT) originate from scientific and technical achievements of Soviet Union's defence industry.

The history of PDT began in the well-known submarine facility SEVMASH where in 1973 the technique’s inventor and DIATECH's Vice President for science and technology, Professor Shuhostanov V.K. for the first time applied PDT by testing submarine pressure hulls.

Scientific production company “Diagnostics technologies for technosphere” (SPC DIATECH, LLC) possess the patent on Phonon Diagnostics Technique since 1997. DIATECH always was the only company in the world with the right to use Phonon Diagnostics Technique, PDT equipment and PDT software, to train PDT specialists. DIATECH’s Research and Training Department has been improving company’s technologies, developing software and hardware for more than 20 years. [3]. PDT projects were implemented for major oil and gas companies all around the world: in Europe, Asia, the Middle East and Africa.

Phonon Diagnostics Technique is based on real-time diagnostics of physics process which goes in material and structure of facilities. This allows to inspect technical condition of industrial facilities without mode change, without interference in the operating process, at different stages of manufacturing, testing, operating and repairing, what leads to considerable financial saving.

Technical capabilities

Technical capabilities of Phonon Diagnostics Technique allow to inspect hard-to-reach facilities including pipelines in concrete insulation and complex geometric shapes, pipe sections passing above and below river bottoms.

Phonon Diagnostics Technique is applicable in a wide range of temperatures and pressures. The temperature of the working environment when installing Phonon Emission Transducers directly on the inspected component’s surface can vary from -20 to +70 °C. Temperature of the operating fluid when installing transducers using waveguides can be from -80 to +400 °C.

PDT fully covers the common range of pipeline diameters and wall thicknesses without restrictions in their length.

When using Phonon Diagnostics Technique, the following types of defects can be identified: loss of metal of corrosive origin (extensive anomaly), single and group pits, cracks, stress-corrosion cracking and others. PDT allows to identify defects by size and depth, type and severity, to determine quantity and location. Application of innovative Phonon Diagnostics Technique is possible in combination with conventional inspection techniques.

Phonon Diagnostics Technique does not require point measurements on surface, instead of this phonon emission is recorded in 100% of inspected component. The product flow rate does not affect inspection results.

Working principle

Onstream industrial facilities (such as pipelines), rather the materials from which they are made, are influenced by effects of different types such as mechanical, thermal, magnetic, i.e. energy effects them from outside. The materials themselves have internal energy, including the energy of the crystal lattice bonds — phonon emission.

There is an interaction of material and energy going in a component under operating conditions, i.e. the energy (E) supplied from the outside interacts with material (M). As a result of this energy interaction, there are processes of redistribution, concentration and release (emission) of energy by the material i.e. phonon emission PhE is formed in the material and around it.

The universal reaction of interaction in terms of "material (structure) – energy" can be written as follows:

E + M = PhE

As a result of interaction between energy and material is various physical processes - corrosion damage, thinning, fatigue damage, and destruction. Phonon emission is most intense and concentrated in places where corrosion, damage, defect formation and destruction are occurring.

Distribution, intensity, concentration and other parameters of phonon emission directly characterize the processes occurring in the structure, determine the state of the material, characterize the technical condition of the structure.

The most important part of Phonon Diagnostics Technique are the advanced software technologies. The software developed by SPC DIATECH, LLC forms the basis of technique. Among other things, detection of defects by PDT is based on the component topology in the process of data collection and processing.

PDT inspection steps

PDT inspection of a pipeline includes: PDT desk set-up, determination of installation location of phonon emission transductors and following inspection steps. The pipeline is divided into sections up to 1 km long in case if phonon emission transducers are installed right on the surface of inspected component. It is possible to carry out inspection of longer areas using waveguides – concentrators of phonon emission (so-called "phonon crystals"). Phonon emission trunducters are installed on cleaned pipeline surface in pits. The duration of the phonon monitoring of each site is usually from 1 to 4 hours depending on the geometry and operating conditions of the facility. [4]

During first steps of inspection a PDT mathematical model of the object is developed and so-called full-scale calibration for each area of the object are carried out .

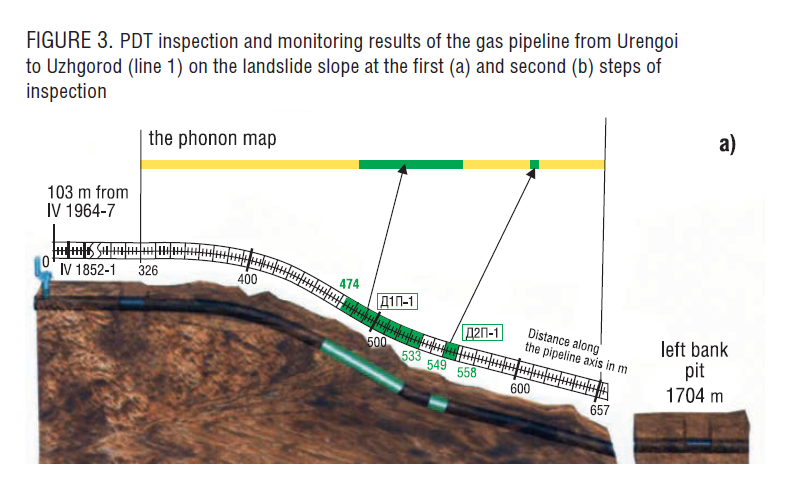

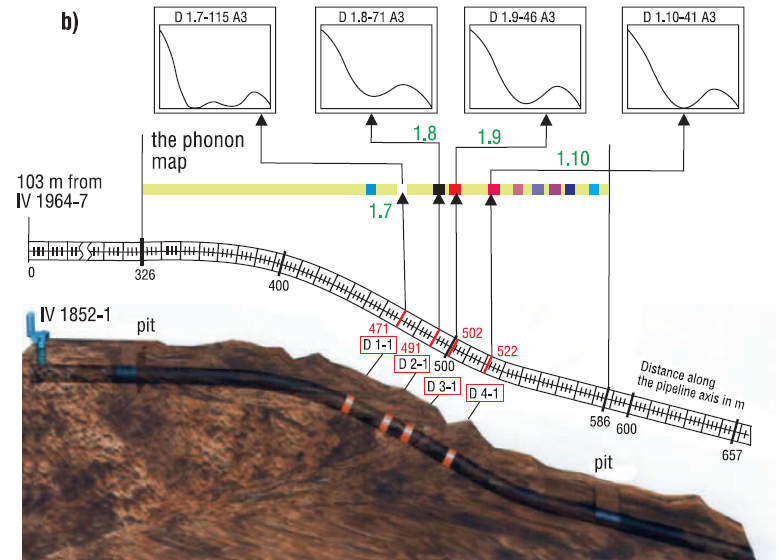

Phonon emission active areas are image on phonon maps presented in pipeline drawings in real-time during monitoring. Active areas position determines the places of known defect formation, unknown defect formation, as well as indications of other character. Thus, by occurrence, position and intensity of an active area, the analysis of defect formation and spatial localization of defects along the length of the pipeline is carried out, a phonon map is created for each inspected area.

Next step is a detailed analysis of each phonon-active area performed with the help of the software developed by SPC DIATECH, LLC. This process determines the way of phonon emission distribution in each area. The physical processes occurring in the defective areas, dimensional characteristics, activity and severity of defects are evaluated based on the analysis results, the further development of defects is forecast.

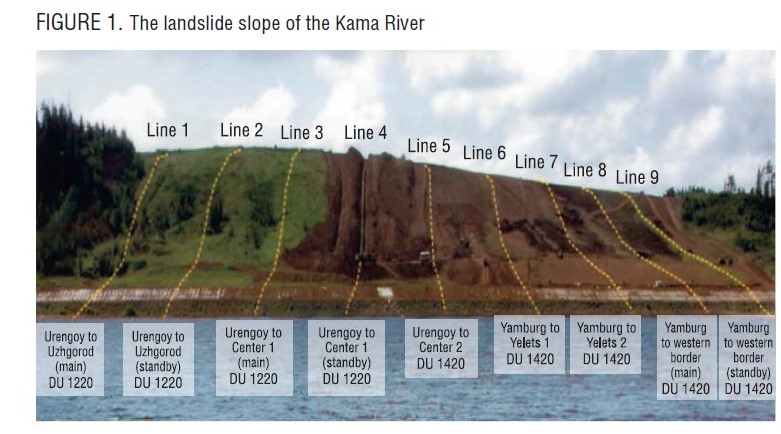

A good example of applying of Phonon Diagnostics Technique on the main pipelines is the project performed on gas pipelines located on a landslide slope of Kama river [2], which are part of the 9-lines Uzhgorod corridor (see Figure 1).

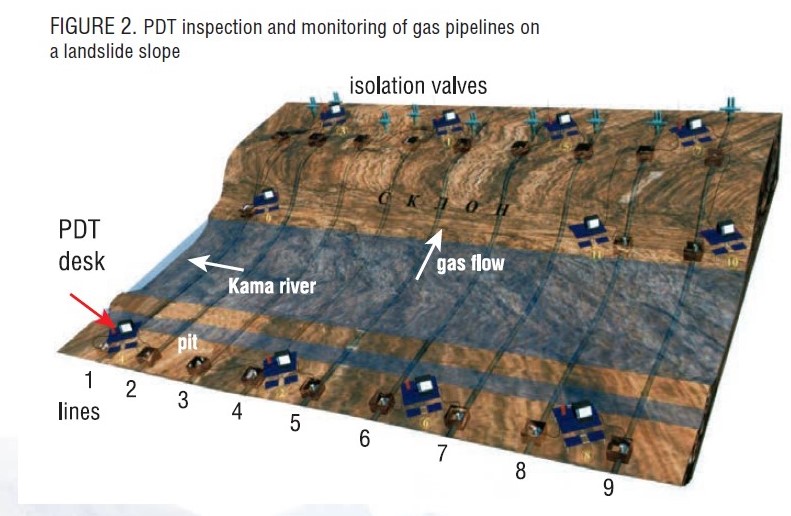

The arrangement of the system equipment is shown in Figure 2.

Example of presentation PDT inspection and monitoring results for Line 1 (Urengoy-Uzhgorod gas pipeline) on the landslide slope at the first (a) and second (b) stages of inspection is shown in Figure 3.

Phonon Diagnostics Technique is implemented as follows [1]. Phonon emission sensors should be installed on the inspected component. Data collection units should be connected to the power source. PDT software should run. Radio synchronization system should be installed at opposite ends of the pipeline to connect PET systems, the protection of radio channels against industrial interference should be evaluated. PET and data collection units should be connected. Inspected object should be calibrated using ready-made models and unique data for each facility. Test monitoring should be performed for 30 minutes to determine the accuracy of calibration for the inspected object and the operability of phonon emission sensors in the data collection mode and the quality of the received signals in the information processing mode. Next step is 2 hours PDT monitoring including collection and processing of information to assess the operation of the registration scheme. If necessary, the monitoring time can be increased. The accuracy of defects location during PDT inspection can be less than 0.15% of the distance between sensors.

In case if the in-line inspection of oil and gas pipelines is impossible or financial unprofitable, Phonon Diagnostics Technique is the only way to inspect the facility. Phonon Diagnostics Technique does not require mechanical movement of equipment or trunducters installation on the facility surface. There are no obstacles to inspect pipeline sections with curved bends, pipes with complex geometric shapes, flanged connections, elbows, etc.

Despite the fact that Phonon Diagnostics Technique is not a scanning, but a screening technique, its results are not only comparable to conventional diagnostic techniques (including in-line inspection), but also surpass them by a number of measures.

Phonon Diagnostics Technique provides quick and hight quality of information processing, reducing of preparation and inspection terms, reducing the complexity of inspection and results processing; this contributes to the expansion of technique application areas.

Since PDT inspection can be provided during operating of a facility, there are no financial losses upon the work completion.

Conclusions

Phonon Diagnostics Technique allows to carry out real-time inspection of physical processes occurring in the structure. Distribution, level, intensity, concentration and other parameters of phonon emission determine the state of the material, characterize the technical condition of the structure.

Unlike in-line inspection, Phonon Diagnostics Technique does not imply significant costs for pipeline preparation and allows to reduce customers costs.

Phonon Diagnostics Technique is actively developing and it’s successful applied on different types of facilities including main pipelines, what is confirmed by such well-known international organizations as Bureau Veritas, Russian Maritime Register of Shipping, as well as by numerous reviews of global oil and gas companies: Total, Conoco Phillips, Cepsa, Repsol, SINOPEC, Gazprom, Rosneft, Lukoil and others.

References

1. Patent RU 2576470 C2 Method of phonon emissive diagnostic. 29.01.2014.

2. Shammazov A.M. Calculation and provision of reliable pipelines in geotechnical conditions.

Part 2. Evaluation and maintenance of pipeline strength in difficult engineering and geological conditions / А.M.Shammazov, R.М. Zapirov, V.A. Chichelov, G.E. Korobkov – М.:»Inter», 2006. – 564 с.

3. http://diatech.ru/company/.

4. Technosphere materials science: encyclopedic reference / comp. Vladimir Perinsky, V.K. Shukhostanov, V.N. Lyasnikov, A.V. Glukhov – Saratov: Sarat. state. Techn. UN-t, 2007. 147 p.